What Is The Process Of An Injection Moulding Trial?

A mould trial is a process by which a new mould is optimised in order to produce the desired products as efficiently as possible. This makes it one of the most important aspects of injection moulding. Most of the time, a standard mould trial process consists of three test phases. Sometimes, several mould trials need to be conducted during a single phase. If necessary, toolmakers need to keep testing and optimising until the product meets customer’s exact requirements and wishes.

Watch the video :https://youtu.be/D1Dmke549s4

This is custom heading elementDescriptionFeedbackDescription Coagulation Analyzer Our company is specialized in plastic injection mold making and plastic injection molding manufacturing, applied for medical equipments such as Urine Strips Sediment Analyzer, biochemistry analyzer, chemistry analyzer, urine analysis machine and son on. Our Advantages of Plastic Injection Parts: Part Material Normal Plastic: PP, PE, EVA, PS;…

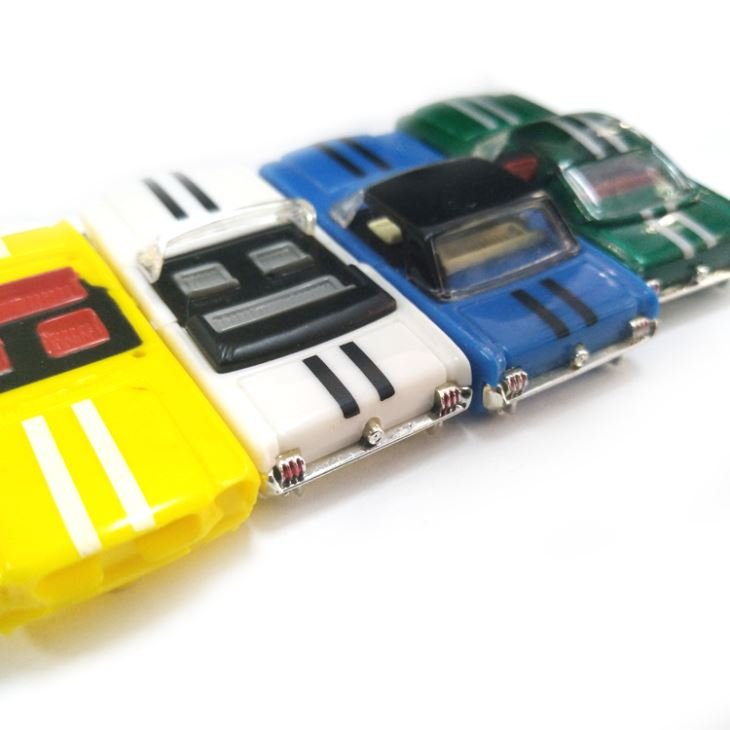

This is custom heading elementDescriptionFeedbackDescription Scale Model Cars Many miniature vehicles were originally aimed at children as playthings. But Precision-detailed miniatures made specifically for adults are a significant part of the market now. Fit Precision Mold Co., Ltd is specialized in producing all kinds of plastic scale model cars and accessories in different scale size,…

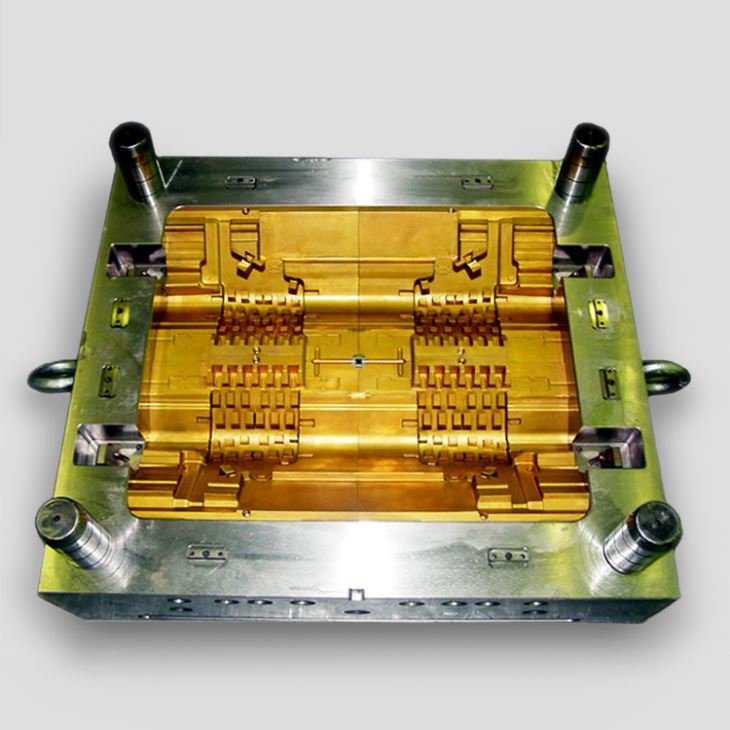

This is custom heading elementDescriptionFeedbackDescription Product description Advantages: 1. Competitive price 2. Strict quality control system 3. Quick mold making and delivery 4. Advanced equipment, excellent R&D teams 5. Professional technicians and rich experienced workers Item Description 1.Mould material P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 2.Hardness of steel vacuum quenching ,nitride,HRC41-47, HRC46-50,HRC60 3.Inserts / Slider steel…

This is custom heading elementDescriptionFeedbackDescription Product Name Plastic Injection Molding – Tool Building – Mold Design & Analysis mould material 45#,P20,H13,718,2738,NAK80,S136. mould base LKM,HASCO Cavity 1 or more Runner cold or hot runner Mould life 45# :300,000-500,000shots P20: 500,000shots 718: 700,000shots Design software UG,PROE,CADetc. Plastic material PP,PE,ABS,PC PET pa66 . Delivery time 30 days Specification with good quality lower price FAQ 1. Q: How long is the lead-time for a plastic injection mold? A:…

This is custom heading elementDescriptionFeedbackDescription Part Name Plastic Injection Tooling for Export Injection Material ABS, PP, PC, PP+GF, PA, PA+GF, PS, POM, PMMA, PC, etc. Steel of Cavity&Core Depends on Product, we help customer to choose the suitable material. Commonly used material are P20,NAK80,718,1.2344,etc. Steel of Mold Base Depends on Product, we will help customer to…

This is custom heading elementDescriptionFeedbackDescription Company Fit Precision Mold Co., Ltd Business Type OEM/ODM Service Products Name Auto Plastic Injection Mould for NISSAN Rearview Mirror Place of Origin Shenzhen,China Quality System ISO9001 Mould life 300,000-1,000,000shots Mould base Material Standard LKM,HASCO,customized Core&Cavity Material Nak80,P20,H718,S136,SKD61,2738,DC53,H13,1.2344…. Products Material ABS,PP,PVC,PET,PA66,PA6, Design Software UG,Pro E Solidwork, AutoCAD, Moldflow…. Runner Hot runner,cold runner Gate…

This is custom heading elementDescriptionFeedbackDescription Product name In-House Tooling Custom Plastic Injection Molding Mold shaping Plastic Injection molding Mold base LKM;HASCO;DME,etc Mold material NAK20,S136,P20.718H,738H,45#,etc Mold cavity Single or Multi Tolerance +/-0.02mm Sprue gate Hot/cold runner;pin-point gate,etc Design software UG,PROE,CAD,SOLIDWORK,etc Product material ABS,PP,PE,POM,PMMA,etc Transportation By sea, by air or by land as you request Package Standard or as you request OEM/ODM Acceptable FAQ 1. Q: What kind of molds do you make? Plastic injection mold, Compression mold or something else? A: We…

This is custom heading elementDescriptionFeedbackDescription Rubber Vibration Dampeners Fit Precision Mold Co., Ltd started to do rubber compression molds at the year of 2004. Full ranges of raw material can be chosen such as NR, NBR, EPDM, SBR, CR, FPM, silicone and so on. Many kinds of parts have been made for automotive industries, medical…